Thin blade cutting and greasing Machine Jingou Y.P.2012

Product info |

|

| MANUFACTURER | JINGOU PACKAGING MACHINERY CO. LTD |

| MODEL | ZBFY 3000 |

| YEAR | 2012 |

| SHEET (mm) | 3250mm (width) |

| PRODUCTION | 180/MIN |

| MATERIALS |

|

-

Specification

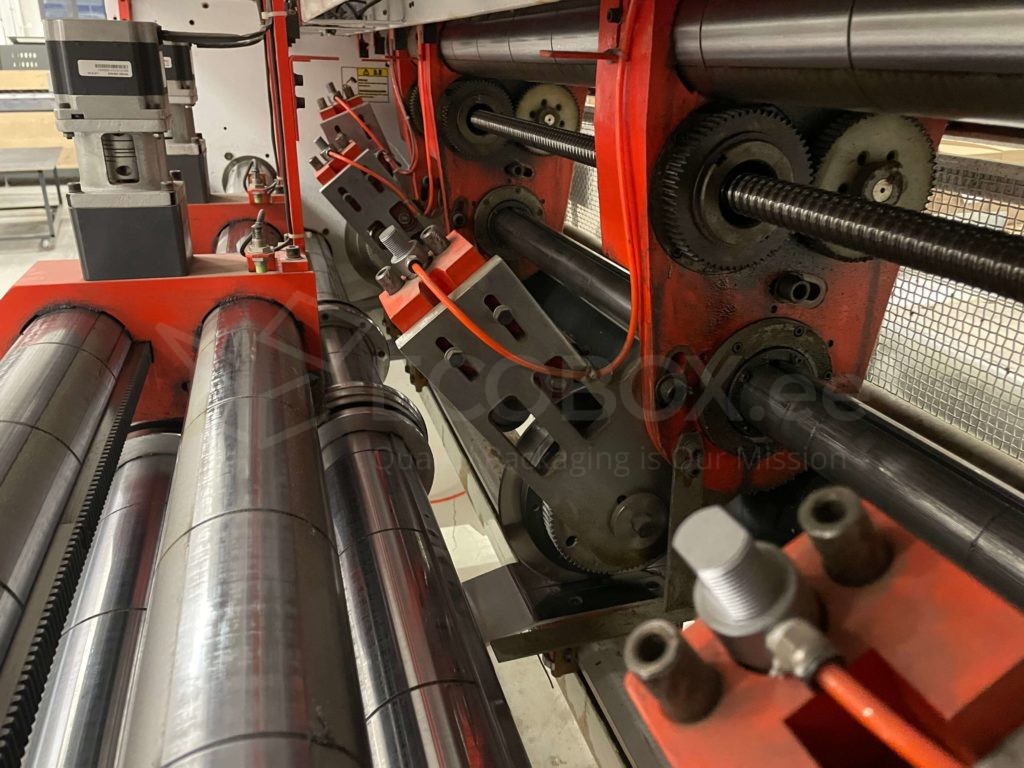

- CUTTING AND GREASING (SLITTER AND SCORER) MACHINE

- MACHINE SIZE: 1565 X 3900 X 1500

- Automatic (motorised) adjustable greasing and cutting units on shafts

- Machine is equipped with thin blade cutting knives with automatic sharpening system

-

Information about ZBFY 300 cutting and greasing machine

Thin blade cutting and greasing machine Jingou ZBFY

Application: for carton & cardboard manufacturer.

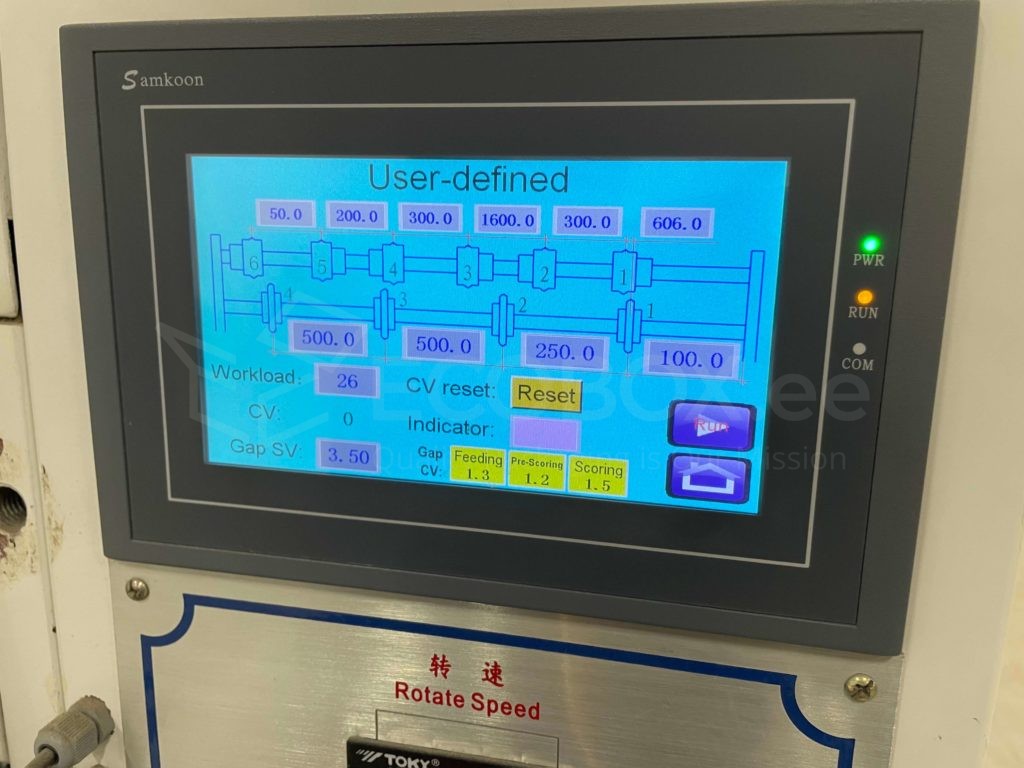

Advantages: this machine is PLC+HMI control, can finish pre-pressing, slitting, scoring, trimming in one time pass. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency.

Operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well.

Productivity: hundreds of all quantity orders per day.

Set up time: 1-30 seconds.

Memory: save 300 orders

Adopts train-type heavy rail as slide way to hold and move slotting and scorer seats. Movement stable and smooth. Min scorer distance is 35mm×100mm, this size applies to more than 95% of small cartons. Machine has intelligent operating system, wich is easy to understand, this eliminates need for skilled workers. When operation system is in automatic mode, it can connect with ERP to scan QR code. This makes order changing easier then ever and leaves no room error. ZBFY 300 can produce hundreds of small amount orders. Machine is well suited for small and medium-sized companies, as it is convenient to quickly manufacture small and medium-sized batches. Theres one button to change over 3,5 or 7 layer cardboard, system adjusts gap automatically.

- Pre-crease wheel, slitter seat, crease wheel be adjusted automatically separately.

- Operate by left and right hand, one key switch. Applicable cardboard thickness: 1.5-15mm(E flute to 7layer )

- Slitting and crease precision: ±0.05

- Automatic or manual feeding available, just one worker can adjust cardboard size, simply and fast.

- Suitable for various of cardboards, feed is stable and accurate.

-

Electric part

- Man-machine interface, PLC control. Robot operate system with humanization, simple structure, easy to maintain.

- Manual and auto one key switch

- Left and right baffle, one key switch

- Drawing choose-easy to choose and operate

- Every day can produce more than 200 orders.

- Change order just need 1-10seconds, save 250m than traditional slitter.

Application: for carton & cardboard manufacturer.

Advantages: this machine is PLC+HMI control, can finish pre-pressing, slitting, scoring, trimming in one time pass. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency.

Operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well.

Productivity: hundreds of all quantity orders per day.

Set up time: 1-30 seconds.

Memory: save 300 orders